As a professional custom bed sheet supplier in China, we transform your unique designs into premium bedding collections. With 10+ years of experience in bed sheet manufacturing, we specialize in complete customization – from premium fabric selection and precise pattern printing to custom sizing and branded packaging. Our comprehensive service helps you build a distinguished bedding collection with guaranteed quality and competitive pricing.

Here we give an example to show how we custom making your designs to elegant, branded bed sheets.

1. Design Consultation

Share your ideas with us – whether you have a preferred pattern style or your own custom design.

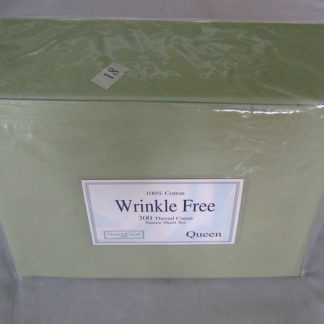

Our technical team works closely with you, offering pattern options based on your ideas or creating designs tailored to your specifications. We carefully consider key factors like pattern repeat dimensions and address any printing limitations.

We ensure perfect color coordination across all components, such as matching a printed duvet cover front with a solid-colored back.

After discussing your requirements, we provide a detailed mockup for your review.

Finally, the customer selected 100% cotton 300TC fabric with reactive printing on the front and a matching solid color on the reverse.

Finally, the customer selected 100% cotton 300TC fabric with reactive printing on the front and a matching solid color on the reverse.

From the picture, you can see that we have adjusted the repeat size to 64 cm to match the rotary printing screen’s repeat dimensions. Additionally, we have chosen pink as the corresponding reverse color

2. Sample development

Once the design is confirmed, we’ll create sample prints to show you exactly how the colors and effects (like cloud patterns or color overlays) will look.

Option 1: if it is machine print, we will do strike offs to show you the color and effect, there is size limitation for strike offs.

Option 2: we can do digital printing exactly same size of the finished products no size limitation for digital printing.

The picture shows that the second strike-off is clearer and more visually appealing than the first. If necessary, we can also produce third and fourth rounds of strike-offs

The picture shows that the second strike-off is clearer and more visually appealing than the first. If necessary, we can also produce third and fourth rounds of strike-offs

3. Production Printing

After sample approval, we proceed with full production printing. The process includes comprehensive pre-treatment and finishing steps. We ensure all quality standards are met – from fabric feel and color fastness to shrinkage control and fabric strength.

This is rotary reactive printing process.

This is rotary reactive printing process.

4. Product Manufacturing

Our team precisely cuts the fabric, performs professional sewing with reinforced stitching, and conducts thorough quality inspections. After ironing and folding, we carefully package your products for shipping, ensuring all items meet our high quality standards.

5. Custom Packaging

We help select appropriate packaging based on your sales channels and market needs. You can choose from gift boxes or PVC bags with customized design cards, all tailored to match your brand identity.

The customer select wired frame pvc bag for the packaging.

The customer select wired frame pvc bag for the packaging.

6. Professional Product Presentation

We capture your products through professional photography, showing their real-life appearance. These images will enhance your marketing materials and attract customers, elevating your brand presence. We ensure all details match your brand standards.

In short: You provide the design, we deliver the finished product.