What is Pinsonic/Ultrasonic/Embossed Quilted fabric?

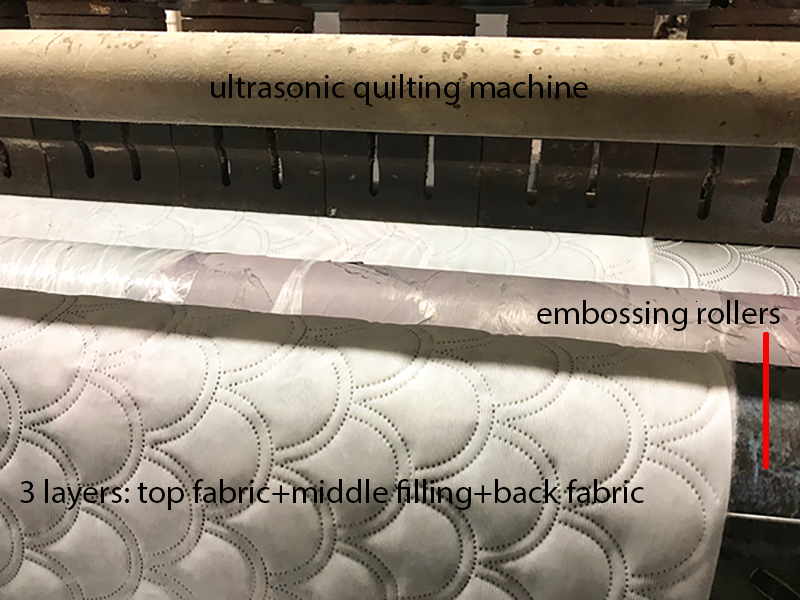

It is a rapid and efficient special ultrasonic quilting machine that uses ultrasonic energy instead of conventional stitching techniques to join the top fabric, middle filling layer, and backing fabric, creating intricate patterns.

The materials are held under pressure and subjected to high-frequency ultrasonic vibrations generated by a piezoelectric transducer. The transducer converts electrical energy into mechanical vibrations, which are amplified and transmitted to the welding horn.

These vibrations produce localized heat at the contact points, causing the materials to melt and bond together, forming a durable and seamless connection.

How are Patterns Created During the Ultrasonic Quilting Process

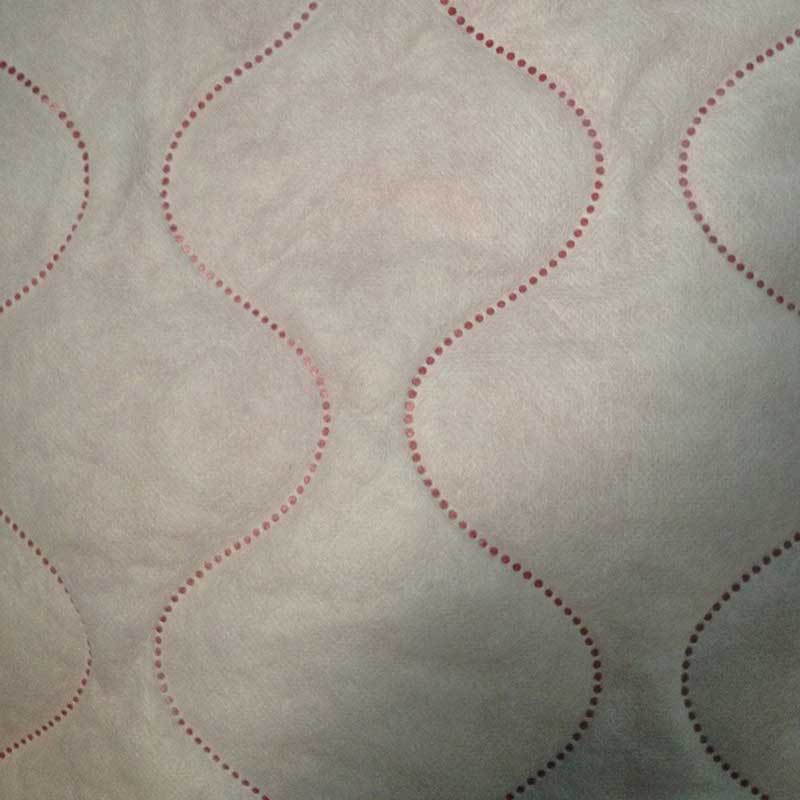

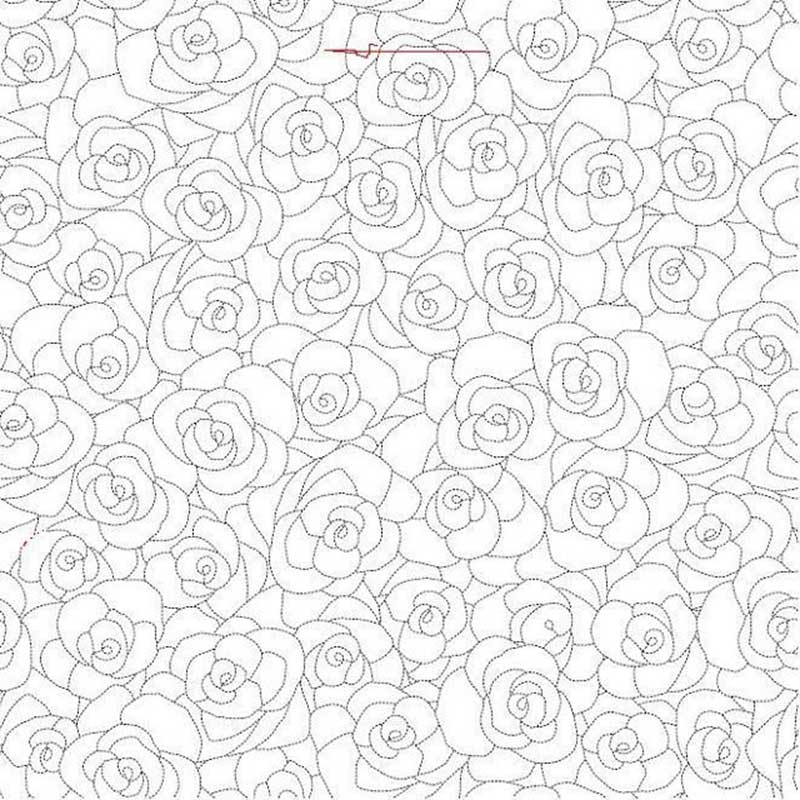

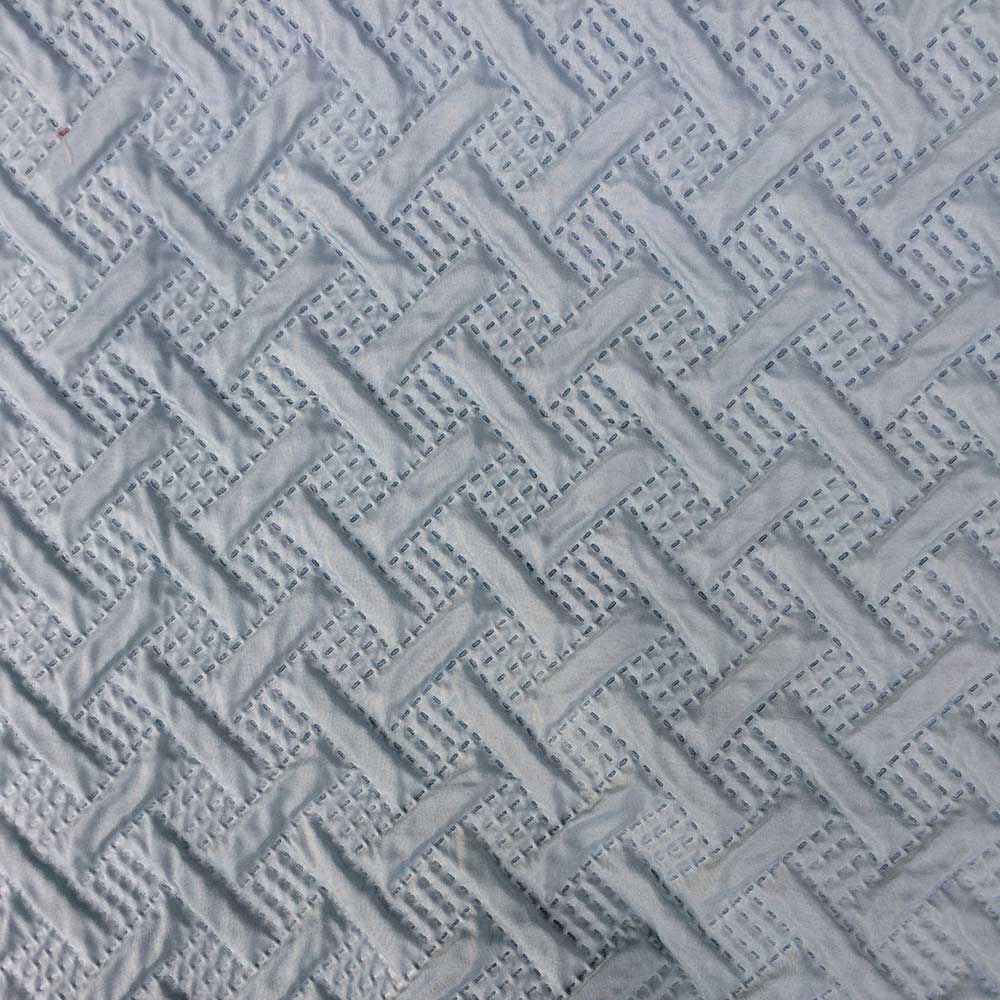

Different patterns require different embossing rollers, which need to be pre-engraved with the desired designs. During the ultrasonic bonding process, the raised areas on the roller create bonding points where ultrasonic energy is focused. These bonding points form continuous tracks on the three-layer fabric assembly, and the areas enclosed by these tracks create the final decorative patterns. The depth and design of the engraved pattern on the roller directly determine the final appearance of the quilted fabric.

What is the difference between thread quilting and pin sonic quilting?

Quilting Method:

Traditional stitched quilting involves sewing fixed stitch patterns through the layers of fabric, batting, and backing.

Pin sonic quilting uses ultrasonic vibrations to locally melt and fuse the fabric layers together, creating seamless quilted patterns without stitching.

Speed:

Stitched quilting is limited by the speed of the sewing machine and needle movement, making it a relatively slower process.

Pin sonic quilting utilizes high-frequency ultrasonic vibrations, allowing for much faster and more efficient quilting.

Applicable Fabrics:

Stitched quilting can be used on a wide variety of fabrics, but may struggle with thicker or harder-to-pierce materials.

Pin sonic quilting mainly used in polyester fabrics such as microfiber, velvet, suede, sherpa fabrics, etc.

Cost

Stitched quilting costs more than pin sonic quilting due to higher equipment prices and slower production speeds.

Although pin sonic quilting requires upfront costs for roller designs, it is more cost-effective overall.

Traditional quilting is done by either hand or machine. Layers are joined together by thread or yarn.

Obviously the pinsonic/ultrasonic/embossed quilting is much cheaper than traditional quilting.

You can select hundreds of quilting pattern from us